Servicii debitare laser la maximă precizie!

Oferim servicii de debitare laser (taiere laser) pentru decuparea tablelor si tevilor de inox sau aluminiu. Precizia ridicata si timpul rapid de executie sunt asigurate de o aparatura performanta si de experienta echipei Profinox!

Serviciile de debitare cu laser presupun o serie de avantaje:

- Universalitate – instrumentul poate fi utilizat pentru o gama variată de materiale, Profinox asigurand servicii de debitare cu laser pentru table si tevi din inox, aluminiu sau cupru;

- Energia introdusa in procesul de taiere laser metal este mai redusa;

- Procedura de taiere laser presupune deformatii minime;

- Costuri reduse pentru taiere cu laser;

- Absenta contactului intre piesa si scula;

- Calitate sporita a suprafetelor;

- Bavuri minime: in procesul de debitare laser metal, acest avantaj aduce cu sine si eliminarea eventualelor prelucrari ulterioare;

- Posibilitatea de realizare a formelor complicate.

In plus, procesul de taiere cu laser este unul siletios si rapid, asigurand o precizie ridicata » de +/- 0,1 mm. Daca aveti materiale a caror grosime depaseste limita maxima pentru debitare cu laser, Profinox va pune la dispozitie si servicii de taiere cu jet de apa.

Daca doriti mai multe informatii despre serviciile noastre, va invitam sa ne contactati sau, daca aveti un proiect in asteptare, puteti solicita o oferta.

Profinox ofera servicii debitare laser pentru table din materiale diferite: inox, aluminiu sau cupru. Utilizam aparatura performanta, prin urmare executam o taiere cu laser la o precizie ridicata. Rezultatele sunt impecabile: precizia instrumentului folosit asigura o debitare laser metal cu minime deformari sau bavuri.

Parametri tehnici pentru serviciile de taiere laser metal:

- Dimensiune maxima coala: 4000 x 2000 mm

- Precizie debitare laser: +/- 0,1mm

- Grosime maxima materiale:

- inox: 15 mm

- aluminiu: 15 mm

- cupru: 8 mm

- viteza maxima taiere cu laser: 60m/s

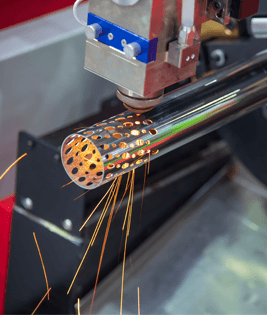

Oferim servicii de taiere laser metal inclusiv pentru tevi, forma sau materialul acestora putand varia. Astfel, asiguram debitare cu laser pentru tevi rotunde sau rectangulare, din inox, aluminiu sau cupru.

Parametri tehnici pentru taiere laser tevi:

- Teava rotunda: ømin 12 mm – max 220 mm

- Teava rectangulara: max. 200 x 200 mm

- Lungime maxima profile: 6500 mm

- Greutate maxima teava: 35kg/m

- Grosime maxima materiale:

- inox: 6 mm

- aluminiu: 6 mm

- cupru: 6 mm

Alaturi de serviciile de debitare laser metal (taiere laser metal), Profinox va pune la dispozitie si servicii de debitare cu jet de apa, Procedura de taiere cu jet de apa presupune, dupa cum ii spune si denumirea, utilizarea unui jet de apa de presiune ridicata (3000 – 6000 bar), cu sau fara abraziv.

Jetul de apa este proiectat prin intermediul unei duze (diametrul 0.25 – 0.5 mm) pe suprafata materialului de taiat. Datorita eforturilor de compresiune si eroziune produse de jetul de apa si abraziv are loc indepartarea metalului si realizarea taierii. Procedeul de taiere cu jet de apa are o calitate deosebita, precizie ridicata si bavurile nule.

Astfel, in cazul in care grosimea materialelor dumneavoastra depaseste valorile maxime posibile pentru debitare cu laser, va putem satisface cerintele debitand aceste piese cu ajutorul masinii de debitare cu jet de apa.

Parametri tehnici pentru debitare cu jet de apa:

- Dimensiune maxima coala: 4000 x 2000 mm

- Grosime maxima materiale:

- inox: 40 mm

- aluminiu: 20 mm

- cupru: 20 mm

Beneficiile procedurii de debitare cu jet de apa:

- timpi de lucru extrem de rapizi

- reducerea costurilor de productie

- eliminarea bavurilor

- decuparea de forme complexe

- taiere cu jet de apa a unor piese de grosimi pana la 40 mm

Alegeti sa colaborati cu profesionisti!

Pentru ca procedeele tehnologice moderne, cum sunt cele de debitare cu laser (taiere cu laser), sa atinga un nivel de executie calitativ, este nevoie de experienta, profesionalism si cunoasterea indeaproape a acestora.

Profinox ofera servicii complexe de debitare laser metal, dar si de debitare cu jet de apa, in functie de necesitatile clientilor nostri.

Suntem aliatul dvs. de nadejde in proiectele pe care le dezvoltati. Executam o gama variata de procedee tehnologice, la cele mai inalte standarde de calitate! Serviciile noastre:

Descoperă acum cum Profinox redefinește standardele în industria procesării oțelurilor inoxidabile din România! Alătură-te comunității noastre pe social media pentru a fi mereu la curent cu cele mai recente inovații, sfaturi utile și oferte speciale. Ne găsești pe Facebook Profinox, Instagram @profinoxromania sau Youtube Profinox.